Introduction

You don’t want to get a walk-in tub because it takes too long to fill a walk-in bathtub up. You get cold and it’s miserable, and you’re not gonna sit 10-15 minutes waiting for that tub to fill up. I can’t tell you how many times I’ve heard that over the past 20 years, and sadly, there’s some truth to that. But the reason that bathers are having that experience with the walk-in bathtub is because of the quality of the plumbing equipment that is being installed on their tub.

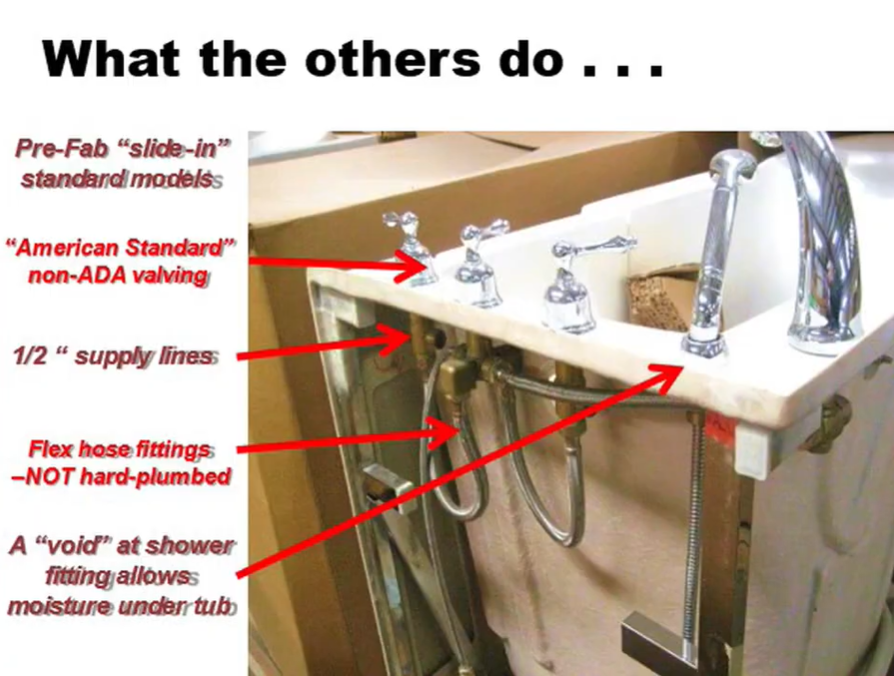

And again, let’s keep in mind some of the best marketers out there are selling the worst products. Our plumbing systems in the United States are primarily, almost always half inch supply lines going into a tub or shower area.

So if I’m one of these mass media, high volume walk-in tub companies, they’re all going to put these five-piece half-inch valves on the deck of the tub. “So I have a hot and cold. I mix the temperature right on the deck of the tub. If I want to run the shower, I have a mechanical diverter” that I use. Well, this violates the ADA because the ADA requires that every source of water, which means your filler spout and your handheld wander, your shower needs to be controlled separately, so that means no diverters. And they both need to be thermostatically protected.

So how do we address this issue? We have three levels and any mix and match between these that we can offer to our clients to help address this issue.

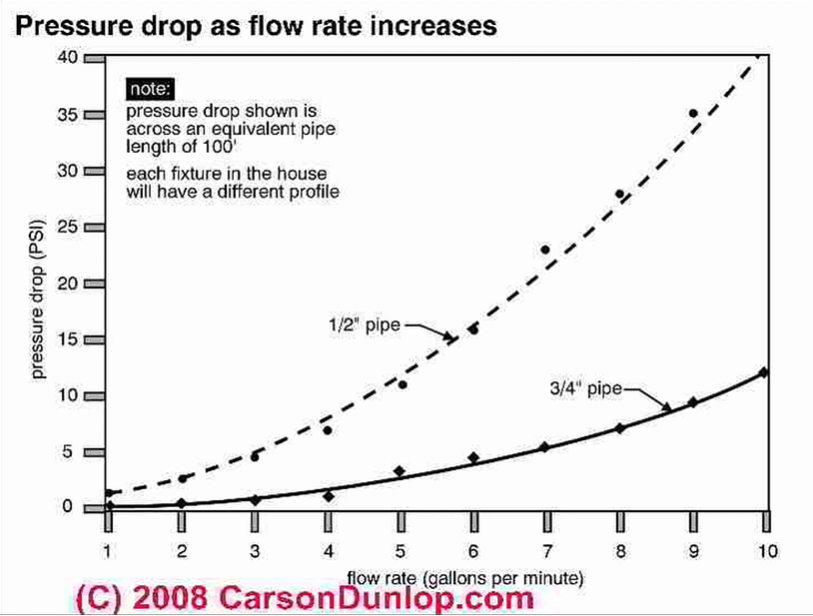

We size up to three-quarter inches in the tub surround. Now I’ve had plumbers tell, “but what are you talking about? You got a half-inch supply line, that’s not gonna improve anything”. Well, actually it does.

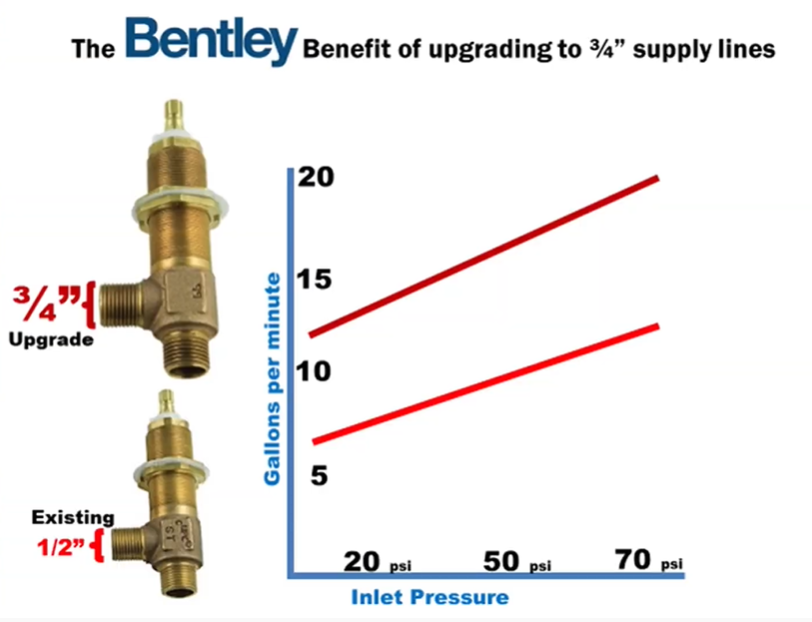

It’s the valves, if you look at these pictures, you can see that our valves in the US are constricted. They may be half-inch couplers, but they’re constricted down to almost a quarter of an inch on the inside. And we get a lot of misinformation because we have these manufacturers that will tell us, “Oh it’s a three-quarter-inch valve”, when in reality the coupler may be three-quarter-inch, but the valve flow through itself is restricted and much smaller than that.

So the first thing we want to do is upsize the lines in the tub and make sure that every valve and junction point in the system is at least three-quarters of an inch. It’s going to reduce the pressure because it’s larger and increase the volume.

And if we do this, then we can maximize your water flow into your tub and now we’re, we’re dealing with your water pressure and your supply system.

But you’ll know if you use a system like we recommend that you’re getting the maximum water flow into your tub, and generally speaking, we can expect to boost up the flow rate into the tub by about 30% by increasing the diameter all the way through the flow system.

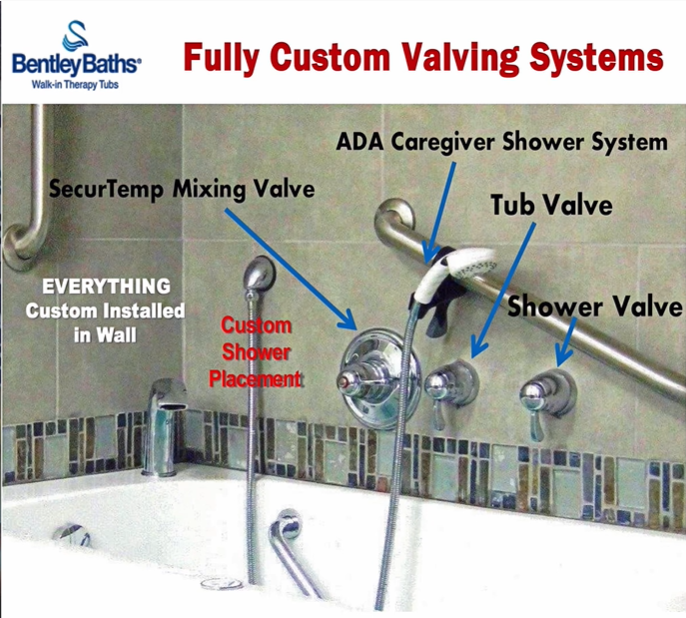

So let’s start now with where we install these valves. The Americans with Disabilities Act ADA, again, says every source of water needs to have its own control. And it also says something very interesting “It says that these controls should be within 30 inches of the back wall and next to the bather”.

So it doesn’t matter whether it’s a tub or a shower, we should never be reaching past our feet to try to adjust the valves and the controls according to the ADA. They should all be next to the bather, and this is also a key feature for caregiving later in life. So let’s keep that in mind too.

So the first thing we can do is can upsize your system to a three-quarter inch. We can put high-quality three-quarter-inch valves on the deck of the tub. We can plummet with the diverter in the handheld shower on the deck of the tub. That is the least expensive way to go, and if you look at the pictures in the marketplace, that’s pretty much what you’re going to see every time.

We’ve trademarked what we call the secure temp valve to meet the ADA guidelines. This is a very high-end type T thermostatic mixing valve.

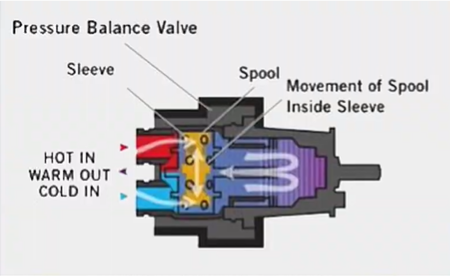

Type T means it’s a true thermostatic valve, which means it’s temperature-driven, not pressure-driven. Most of the valves we use in the United States, if you go down to Home Depot, these primarily pressure balance, which means if the water pressure hotter code one side or the other fluctuates, this mechanical valve attempts to adjust that to keep it close to the temperature it was set at.

But there can be a wide fluctuation of temperature in that kind of valve, so it’s not always safe.

A type T valve is a much more expensive valve and it will first of all shut the flow off if it hits a scald level.

But the most important function on a day-to-day basis is it will not let the water temperature fluctuate more than half a degree one way or the other. Now that’s our secure tip, there are a lot of different quality levels of these valves, but we want to go to the very highest and most effective.

When I put a rapid flow three-quarter inch type T thermostatic mixing valve hard plumbed in the wall in this system that now permits me to accomplish the goal of separating the flow from the filler system in the shower.

Again, I think everything in your system should be hard-plumbed. Meaning copper or something that is not a flexible connector within the system, especially if it’s under the tub. Now, your handheld one on the outside of the tub, that’s a different story. It’s okay to use a flexible hose as long as it’s exposed because it’s easily replaced if you create or develop a leak over time. So our deluxe level will put the thermostatic mixing valve in the wall, headwall, or side wall, depending on the installation.

And we’ll use the hot and cold flow valves as gate valves to control where the water goes.

Our custom level, which is the highest level we now take an interior diameter of three of quarter inches, these valves will flow 20 gallons a minute each. They’re the largest flow valves in the industry for residential use.

And we plumb those next to the thermostatic mixing valve as you can see.

Why do we do this? We do this because the ADA guidelines say these controls need to be next to the bather. Now everything is next to the bather, we can put the handheld shower on an ADA compliance slider bar next to the bather, total control over the process, and easy access.

So why would you invest in these different levels of valving on a tub?

The basic levels – you go there if you’re on a budget, you can’t afford the higher levels.

Higher Levels – If you can afford the higher levels, I definitely recommend that you consider investing in them.

So why would you do this? What’s the point? There are three reasons that you’d want to consider investing in either the deluxe mid-level or the custom level with everything on the back wall.

1. Safety

The first is safety. We’re trying to create the safest environment possible for every one of our customers.

2. Independent Bathing

The second is, when I properly install these valves based on the individual customer’s needs and abilities, I’m going to enhance their ability to bathe independently for as long as possible. And as an example, my dad, as you may or may not know, made it to 102.

And my father was living independently until his very last day. He passed in his own home. But my dad at 102 could bathe himself independently. Why? He could manage this process because of the way we had designed his bathing environment. But at 102, he was getting to the point where we realized, in the near future we might need to bring somebody in to help him a little bit with that bathing process. The key is, if he couldn’t bathe himself independently, then that’s when many people are forced into nursing homes.

3. Care-Giving at Home

And third is designing the environment now for caregiving. And if we do this, our standard tubs will fill in three to five minutes. We’ll talk about the draining process in another video, but they’re gonna drain in three to five minutes. And this is very comfortable for people. Nobody’s ever complained about this, but the key is these negative complaints in horror stories that you hear about are because what companies are selling people, it’s not inherent to the fact that it’s a walk-in tub that you’ve going to have these problems.